ILC has developed lubrication systems and applications that are currently installed by leading manufacturers.

In the industrial sector, ILC provides a wide range of advanced lubrication solutions designed to ensure machine longevity and eliminate downtime. Our conveyor lubrication systems, in particular, play a vital role in maintaining continuous operation and extending equipment lifespan.

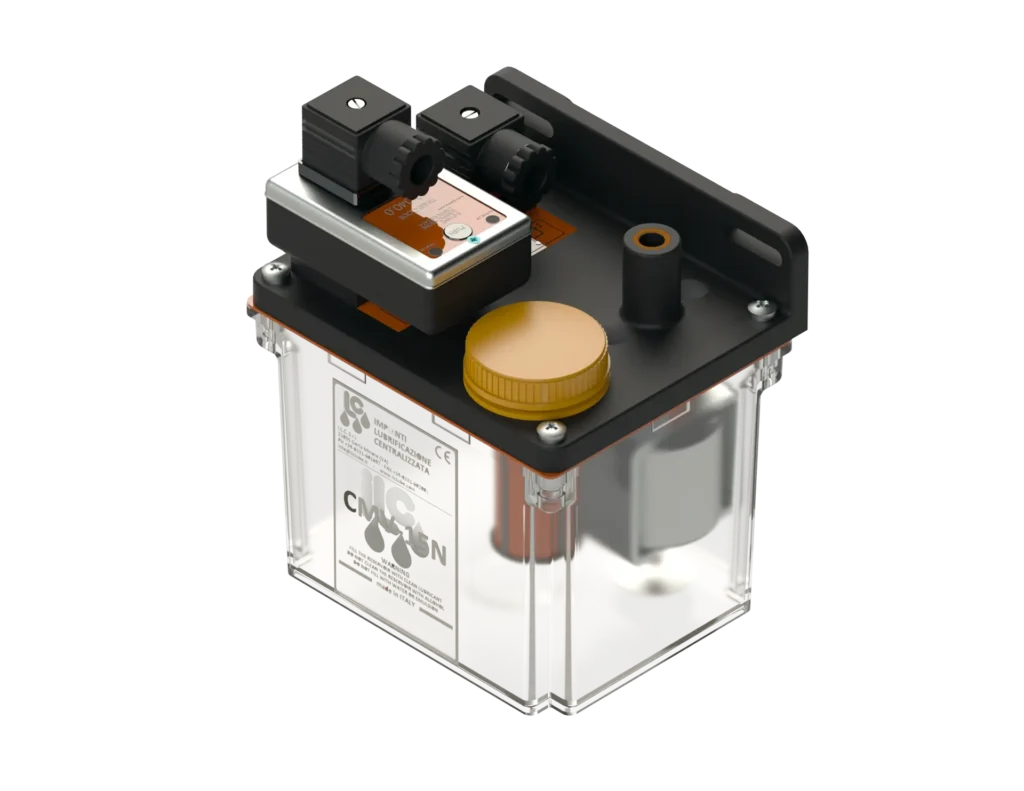

ILC has developed and implemented lubrication technologies that are trusted by leading manufacturers worldwide. Our product range includes everything from simple manual lubrication systems with volumetric metering to fully automatic oil and grease systems featuring progressive metering devices. These solutions are ideal for lubricating shafts, supports, and bearings in medium to large-scale machinery.

We also offer minimal air-oil lubrication systems, specifically designed for tool cooling and lubrication, as well as for gears, rotating head bearings, and electric spindles involved in material removal and forming operations.

For conveyor systems, our minimal lubrication solution is particularly suited to ensure precise, efficient, and environmentally friendly tool cooling and lubrication.

Related product

Here are some systems used in this sector

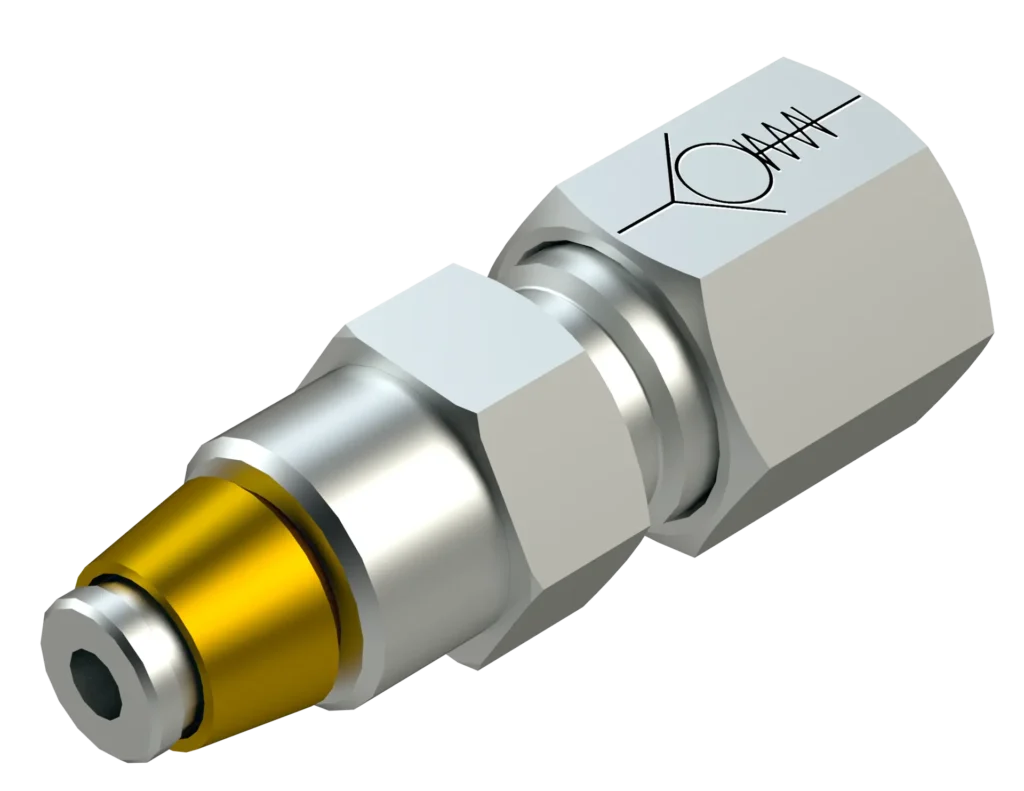

Fitting and accessories

ILC offers a complete range of fittings and accessories designed to ensure optimal performance and reliability in every lubrication system.

Dualine lubrication

The electric TWIN-2 has been designed for all applications that use Double Line Systems. The Double Line lubrication systems, generally

Volumetric InjectorFlow lubrication

The volumetric injector system distributes oils and greases up to NLGI 2 consistency to lubricate friction points in mining machines