ILC lubrication systems applied in these sectors are mainly grease-based and consist of volumetric valves.

Mining environments are among the toughest for machinery: extreme loads, continuous operation, dust, humidity, and high temperatures put every component to the test. Our centralized lubrication systems are engineered to withstand these harsh conditions and deliver consistent performance where reliability is critical.

Key benefits include:

- Maximum equipment availability: reducing unplanned downtime in excavators,

haul trucks, crushers, and conveyors. - Extended service life: protecting pins, bushings, bearings, and chains from

premature wear. - Operator safety: automatic lubrication reduces manual intervention in hazardous

areas. - Cost optimization: efficient grease and oil usage minimizes maintenance costs

and energy losses.

With heavy-duty pumps, robust progressive or dual-line systems, and full monitoring capability, our solutions are proven to support the productivity and safety of mining operations worldwide.

Related product

Here are some systems used in this sector

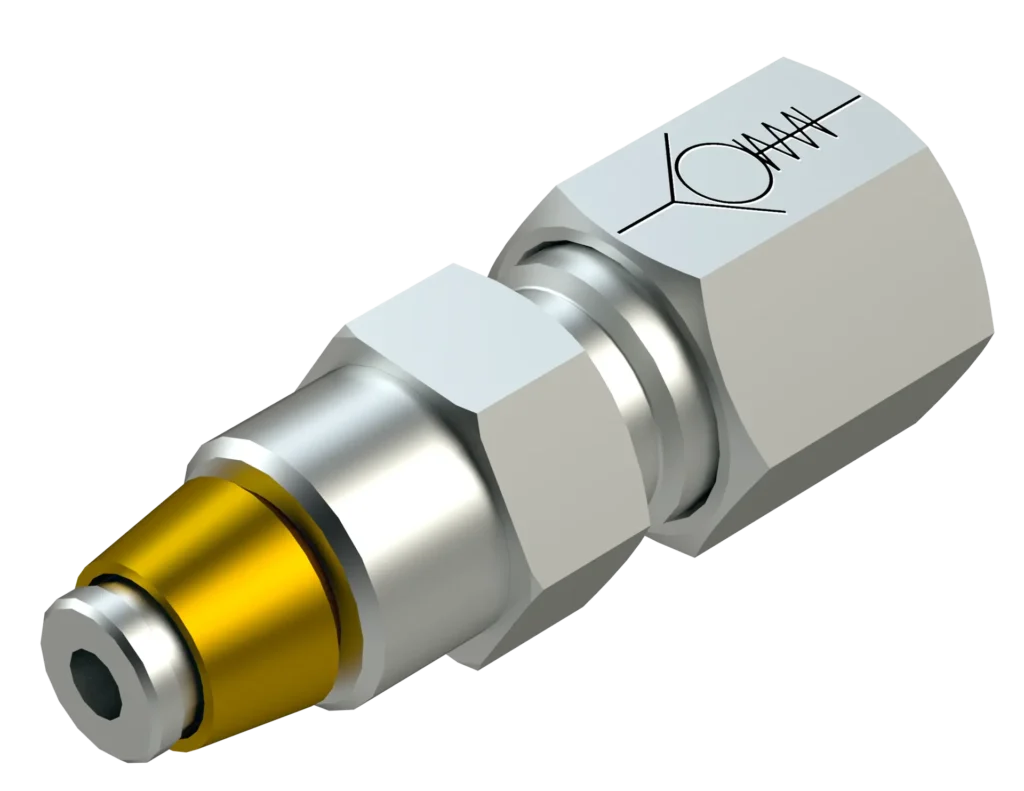

Fitting and accessories

ILC offers a complete range of fittings and accessories designed to ensure optimal performance and reliability in every lubrication system.

Dualine lubrication

The electric TWIN-2 has been designed for all applications that use Double Line Systems. The Double Line lubrication systems, generally

Volumetric InjectorFlow lubrication

The volumetric injector system distributes oils and greases up to NLGI 2 consistency to lubricate friction points in mining machines

Progressive lubrication

The progressive lubrication systems distribute oils, soft grease or grease up to the NLGI 2 consistency, to lubricate the friction