ILC lubrication systems for renewable energy

ILC has developed lubrication systems and applications that are currently installed by leading manufacturers. They range from simple manual lubrication systems with a single point and centralised distribution to fully automatic grease systems that lubricate shafts -supports and bearings in medium-large sized machinery.

Enhancing Wind Turbine Durability and Reliability

The requirements of wind turbine bearings have led to a number of developments to further improve the operation of the ILC centralised lubrication systems, developments that culminated in the creation of a package of solutions that can be used by wind farms around the world, thanks to which they increase the durability and reliability of the systems. Some bearings in wind turbines need to be lubricated effectively at preset intervals and to do so, automatic centralised systems are required. ILC also suggests using a pinion to automatically lubricate open gears.

Related product

Here are some systems used in this sector

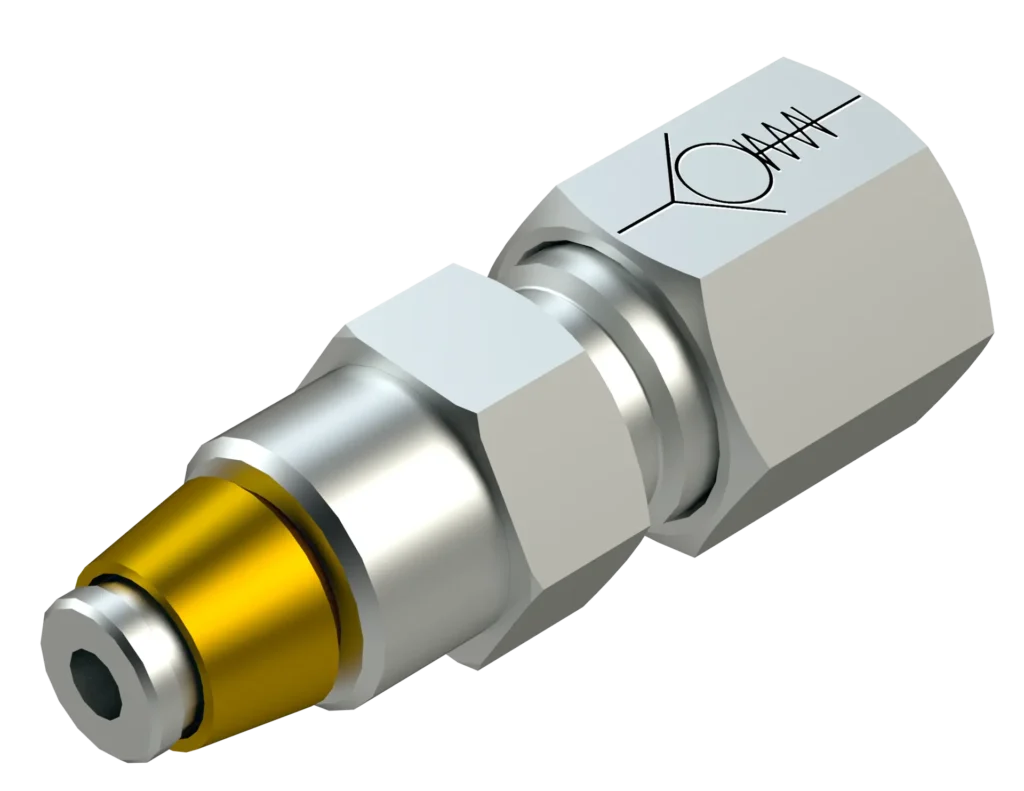

Fitting and accessories

ILC offers a complete range of fittings and accessories designed to ensure optimal performance and reliability in every lubrication system.

Dualine lubrication

The electric TWIN-2 has been designed for all applications that use Double Line Systems. The Double Line lubrication systems, generally

Volumetric InjectorFlow lubrication

The volumetric injector system distributes oils and greases up to NLGI 2 consistency to lubricate friction points in mining machines

Progressive lubrication

The progressive lubrication systems distribute oils, soft grease or grease up to the NLGI 2 consistency, to lubricate the friction